PC hollow sheets, also known as polycarbonate hollow sheets, have emerged as a transformative material in various industries due to their exceptional durability, lightweight nature, and versatile applications. Made from polycarbonate, a strong and resilient thermoplastic, these sheets have taken center stage in construction, automotive, and architectural applications, among others. In India, the growing prosperity of various sectors has given rise to the demand for PC sheets, leading manufacturers to innovate and adapt them to meet specific needs. This Pulkit Plastic Products explores the features, benefits, applications, and market trends surrounding PC hollow sheets, providing insights for those interested in leveraging this material.

Understanding Polycarbonate Sheets

Polycarbonate sheets are known for their high impact resistance and lightweight nature. Unlike traditional glass, which can shatter upon impact, polycarbonate maintains its integrity even under extreme conditions. This characteristic makes it a popular choice for applications where safety is paramount. Polycarbonate is also UV-resistant, ensuring that the material does not yellow or degrade when exposed to sunlight, further enhancing its longevity.

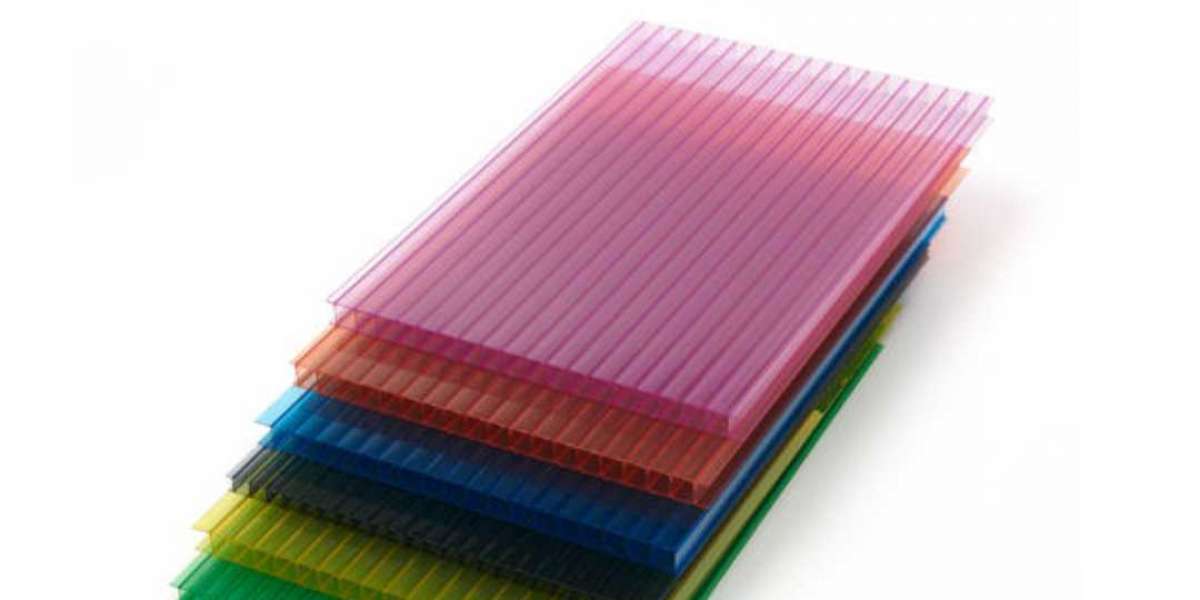

PC sheets in India are available in various thicknesses, colors, and profiles, serving a multitude of purposes. From roofing solutions to partitions, polycarbonate sheets are available in both solid and hollow configurations. Hollow sheets, in particular, are designed with internal chambers that provide enhanced insulation, making them effective in temperature regulation. This thermal efficiency is a vital trait in regions with fluctuating climate conditions.

Additionally, polycarbonate sheets can be easily cut, molded, and shaped, allowing for straightforward installation and versatility in design. They can be fabricated for curved applications, expanding their use in both residential and commercial settings. As a result, polycarbonate hollow sheets have gained popularity among architects and builders looking for innovative solutions that combine aesthetics with functionality.

Advantages of PC Hollow Sheets

One of the significant advantages of PC sheet in India is their lightweight nature. Weighing considerably less than glass, they are easier to handle and install, reducing labor costs and installation time. Furthermore, this lightweight property does not compromise structural integrity, making these sheets suitable for a variety of applications where weight is a concern, such as in canopies or greenhouses.

Another major benefit is their remarkable impact resistance. Polycarbonate is known for being virtually unbreakable; it can absorb more energy compared to other materials such as glass or acrylic. This makes it an ideal choice for safety-critical applications, such as in sports facilities or protective barriers. Additionally, PC sheets can withstand temperatures ranging from -40°C to 120°C, making them suitable for various climate conditions.

The insulating properties of polycarbonate hollow sheets add further value to their usability. The structure of the hollow chambers provides excellent thermal insulation, which can reduce energy consumption associated with heating and cooling. This energy efficiency not only helps lower utility costs for homeowners and businesses but also promotes environmental sustainability by minimizing reliance on non-renewable energy sources.

Application Spectrum of PC Hollow Sheets

The applications of polycarbonate hollow sheets are extensive and varied. In the construction industry, they are commonly used for roofing, allowing natural light while providing protection from the weather. These sheets can create inviting spaces, such as patios or skylights, without compromising on safety or insulation. Businesses such as nurseries often use PC sheets for greenhouse roofing, as they allow sunlight to penetrate while maintaining temperature control.

In the automotive sector, polycarbonate is often utilized in the production of lightweight yet durable parts, including headlights and windows. The strength-to-weight ratio of polycarbonate makes it an attractive choice for manufacturers looking to reduce vehicle weight while maintaining safety standards. This reduction in weight contributes to improved fuel efficiency and lower emissions, aligning with modern automotive standards that prioritize sustainability.

Moreover, architectural applications have seen a significant rise in the use of polycarbonate hollow sheets. Their versatility in design means that architects can create visually appealing structures with unique shapes and forms. Additionally, the aesthetic value of colored or patterned polycarbonate sheets can enhance the visual appeal of buildings while providing functional benefits such as UV protection and temperature regulation.

Market Trends in India

As India undergoes rapid economic growth, the demand for durable and versatile materials like PC sheets is rising. Increased investment in housing, commercial infrastructure, and industrial facilities has led to a robust market for polycarbonate sheets. Manufacturers are responding to this demand by developing innovative, high-quality products that meet industry standards.

The trend toward sustainable construction materials is also gaining traction in India. Builders and architects are increasingly looking for materials that not only provide excellent performance but also contribute to sustainable practices. The energy-efficient properties of polycarbonate hollow sheets align with this movement, as they minimize energy consumption and lower carbon footprints.

Furthermore, green building initiatives supported by the Indian government have encouraged the adoption of materials that enhance energy efficiency. As more projects strive for green certification, the use of polycarbonate sheets is expected to increase. Manufacturers are also exploring the use of recycled content in their products, adding an additional layer of environmental responsibility.

Challenges in the Adoption of PC Hollow Sheets

Despite the numerous advantages of Polycarbonate hollow sheets, certain challenges can hinder their widespread adoption. One of the primary concerns is the potential for scratching and surface abrasion. While polycarbonate is incredibly strong, it can be susceptible to surface scratches, which can impact its aesthetic appeal. Manufacturers are actively working on applying coatings to enhance scratch resistance, but consumers need to be made aware of proper handling during installation and use.

Another challenge is the initial cost, which is often perceived as higher than traditional materials like glass or standard plastic. Although the long-term savings derived from energy efficiency may offset the initial investment, some consumers still hesitate due to the upfront costs. Educating consumers about the life-cycle savings and performance benefits of polycarbonate sheets is crucial in overcoming this obstacle.

Additionally, proper installation is critical for ensuring the longevity and performance of PC sheets. Without adequate knowledge, improper installation can lead to issues such as water leakage or thermal expansion problems. Therefore, it is essential for consumers to engage skilled professionals for installation and maintenance. This focus on professional expertise not only safeguards the investment but also enhances the overall effectiveness of the material.

The Future of PC Hollow Sheets

Looking ahead, the future of polycarbonate hollow sheets appears promising. As technology continues to advance, we can anticipate the development of even more durable and efficient products. Innovations in manufacturing processes may allow for the creation of thinner, lighter sheets without sacrificing strength, thereby broadening their application scope.

With an increased emphasis on environmental responsibility, polycarbonate manufacturers are expected to pursue sustainable practices actively. This includes utilizing recycled materials, reducing energy consumption during production, and implementing closed-loop processes. Such innovations will allow the market for polycarbonate sheets to align with the growing demand for eco-friendly solutions.

Furthermore, collaborations between manufacturers, architects, and urban planners can drive the development of smart constructions that incorporate smart materials like PC hollow sheets. These sheets can be integrated with IoT technologies to enhance building performance, promote energy efficiency, and optimize environmental conditions. Such advancements will likely lead to the emergence of visionary architectural designs that harmonize aesthetics with functionality.

Conclusion

PC hollow sheets, or Polycarbonate sheets, have proven their worth across a multitude of applications due to their exceptional strength, lightweight, and versatility. As industries move towards more sustainable avenues, polycarbonate sheets have emerged as a frontrunner in accommodating both performance and environmental considerations. The growing demand for robust and energy-efficient materials in India has paved the way for innovations that will only enhance the usability and functionality of these sheets.

As we navigate through the challenges and opportunities presented by this material, it is clear that PC hollow sheets will continue to play a significant role in shaping the future of construction, design, and environmental sustainability.

Frequently Asked Questions

Q1: What is the primary use of polycarbonate sheets?

A: Polycarbonate sheets are primarily used in construction for roofing, skylights, and partitions due to their impact resistance, lightweight nature, and excellent insulation properties.

Q2: Are PC hollow sheets suitable for outdoor use?

A: Yes, PC hollow sheets are ideal for outdoor use as they are UV resistant, providing protection from sun damage, and have high durability, making them appropriate for exposure to various weather conditions.

Q3: How do polycarbonate sheets compare to glass?

A: Polycarbonate sheets are much lighter than glass and are virtually unbreakable, making them safer for many applications. However, they can be prone to scratching if not handled properly, whereas glass provides superior clarity.

Q4: Can polycarbonate sheets be customized?

A: Yes, polycarbonate sheets can be easily cut, shaped, and tinted in various colors to meet specific design and functional requirements, making them a versatile choice for many industries and applications.