XTEN-AV is transforming how AV professionals approach design and documentation by replacing outdated methods with intelligent, automated tools. Yet many AV integrators and designers still rely on traditional CAD workflows that were built for another era. While these methods once defined precision and structure in AV projects, they are now increasingly becoming a barrier to efficiency, speed, and scalability.

Outdated CAD workflows may seem familiar and comfortable, but they slow down project timelines, increase errors, and limit collaboration in a fast-moving AV industry. This blog explores why sticking to these old processes can harm AV efficiency and how modern tools can resolve these issues.

1. The Growing Complexity of AV Projects

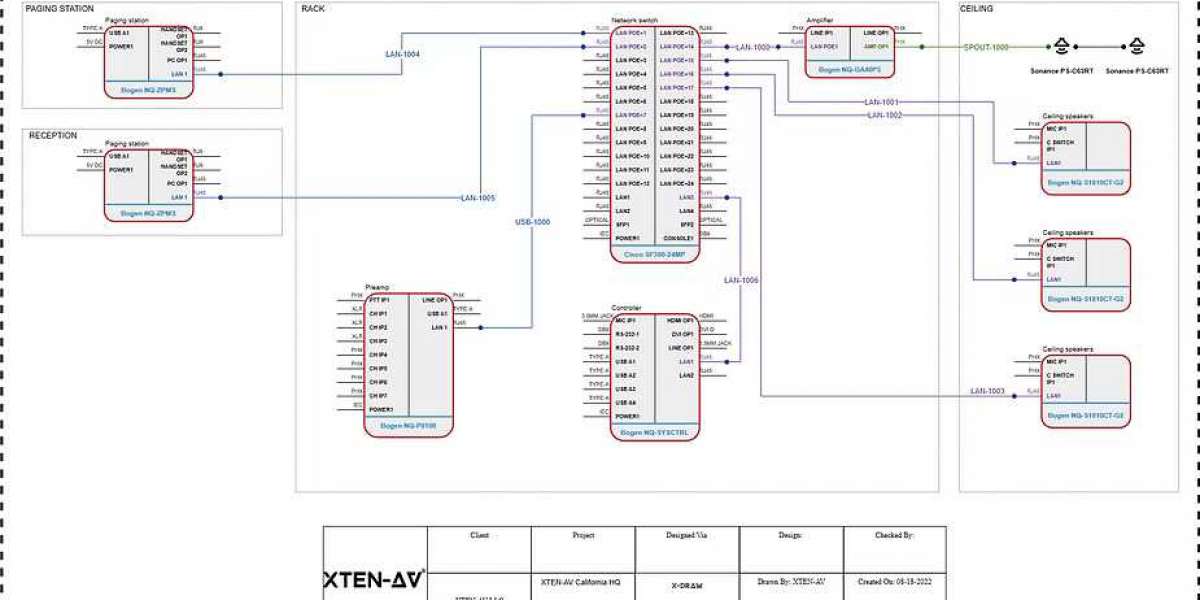

Modern AV systems are no longer simple setups involving a few displays and speakers. Today’s installations include networked audio systems, interactive displays, cloud-based control platforms, and integrated lighting. Designing such systems requires more than basic CAD diagrams.

Outdated workflows often rely on manually drawn schematics and floor plans that do not adapt well to this complexity. Every change in device placement, signal routing, or equipment specification requires redrawing or manual updates. This slows down the entire design process and increases the likelihood of missed details.

2. Lack of Automation Leads to Wasted Time

Traditional CAD workflows rely heavily on manual input. Integrators must manually calculate cable lengths, throw distances, speaker coverage, and power requirements. This approach consumes valuable time that could otherwise be spent on system optimization or client consultation.

Modern AV design tools automate many of these steps. When you adjust a projector location, for example, the software can automatically recalculate throw distance and suggest compatible lenses. With outdated CAD workflows, every adjustment involves a series of manual recalculations that increase the risk of errors and delay project delivery.

3. Limited Device Libraries Slow Down Design

Generic CAD software typically lacks preloaded AV device libraries. Designers often spend hours creating custom blocks or symbols for projectors, displays, speakers, control units, and network components.

These repetitive tasks not only slow the workflow but also introduce inconsistencies between projects. If different designers create different symbols for the same device, documentation becomes confusing and harder to maintain.

Modern AV platforms provide extensive device libraries that allow designers to drag and drop components into their projects. This eliminates the need for repetitive manual work and speeds up the creation of accurate system designs.

4. Error-Prone Documentation Processes

Outdated CAD workflows often involve maintaining multiple separate documents for floor plans, rack layouts, wiring diagrams, and signal flows. Synchronizing changes across all these documents manually is both time-consuming and error-prone.

For example, if a display size is changed in the layout drawing but not updated in the wiring diagram, the installation team may end up with mismatched components. Such errors lead to expensive site corrections and reduced client confidence.

Modern AV software integrates all these elements into a single environment. When a change is made in one part of the design, it automatically updates across related documents, ensuring accuracy and consistency.

5. Poor Collaboration Slows Down Projects

In traditional CAD workflows, collaboration usually means exchanging files via email or shared drives. Multiple versions of drawings circulate among teams, leading to version conflicts, miscommunication, and delays.

AV projects involve designers, engineers, installers, and project managers, often working from different locations. Without real-time collaboration, teams waste time waiting for updates, manually merging changes, and resolving conflicts.

Modern cloud-based AV tools allow multiple users to work on the same project simultaneously. Everyone sees real-time updates, which improves communication, speeds up decision-making, and keeps projects on schedule.

6. Difficulty Adapting to Design Changes

Client requirements often evolve during the design or installation phase. Traditional CAD workflows are rigid and slow to adapt to these changes.

If a client decides to switch to a larger display or add new control features, outdated workflows require designers to redraw diagrams, adjust cable calculations, and update documentation manually. This process can take days and disrupt project timelines.

With modern AV platforms, design changes are easy to implement. Automated calculations and synchronized documentation mean that updates ripple through the entire project instantly, saving time and reducing the risk of inconsistencies.

7. Lack of Integration with Project Management Tools

Traditional CAD software is typically standalone and does not integrate with project management platforms. This disconnect means that timelines, resource planning, and task tracking are managed separately, often through spreadsheets or external tools.

This separation creates information gaps. Designers may not be aware of installation schedules, procurement timelines, or budget changes in real time. As a result, AV projects become less coordinated and more prone to delays.

Modern AV solutions integrate design and project management in one platform. Designers can link drawings to schedules, assign tasks, and track progress without switching between tools. This creates a more efficient and transparent workflow.

8. Outdated Workflows Limit Scalability

As AV companies take on larger or multiple projects simultaneously, outdated CAD workflows become a bottleneck. Manual processes do not scale well.

Managing multiple design files, coordinating teams, and ensuring consistency across projects becomes increasingly difficult. This limits a company’s ability to handle high volumes of work efficiently.

Modern tools are built for scalability. Automated processes, cloud-based collaboration, and integrated project tracking allow teams to manage multiple complex projects without sacrificing speed or accuracy.

9. Missed Opportunities for Innovation

Sticking to outdated CAD workflows means missing out on the benefits of modern technologies like AI-driven design assistance, real-time visualization, and automated documentation generation.

These innovations not only make workflows faster but also improve design quality. For example, automated speaker coverage mapping ensures optimal audio performance, while real-time visualization helps clients understand designs better. By clinging to old methods, AV professionals lose their competitive edge.

10. Conclusion

Relying on outdated CAD workflows may feel familiar, but it is a costly habit in today’s fast-paced AV industry. Manual calculations, fragmented documentation, poor collaboration, and lack of integration all contribute to inefficiency and project delays.

XTEN-AV highlights how modern, intelligent design platforms solve these problems through automation, real-time collaboration, and integrated workflows. By moving away from outdated methods, AV professionals can reduce errors, accelerate project delivery, and focus on creating innovative solutions that meet client needs.

Efficiency is no longer optional in AV. Embracing modern workflows is the key to staying competitive, delivering high-quality projects, and meeting the growing demands of the industry. The sooner teams adopt smarter tools, the faster they can move from design to execution with confidence and precision.

Read more: https://whatson.plus/blogs/82549/Why-AV-Integrators-Lose-Time-with-Generic-Design-Software