In today's highly competitive manufacturing and customization industries, precision and speed are non-negotiable. Whether you're branding products, adding serial numbers, or engraving intricate designs, the technology you choose can make all the difference. One solution stands out as the future of industrial marking — the fiber laser marking machine. This revolutionary tool is not just another piece of equipment; it’s a complete game-changer for businesses seeking efficiency, accuracy, and versatility.

Modern consumer products require labels, logos, and codes that are precise and durable. Traditional methods like ink printing or mechanical engraving often fall short, resulting in faded marks, uneven finishes, and high maintenance costs. A fiber laser marking machine solves these problems effortlessly. It uses high-powered, ultra-precise laser beams to etch materials like metal, glass, leather, acrylic, and plastic with immaculate detail — achieving depths as fine as 0.001 mm. The results are permanent, scuff-resistant markings that enhance both aesthetic appeal and functionality.

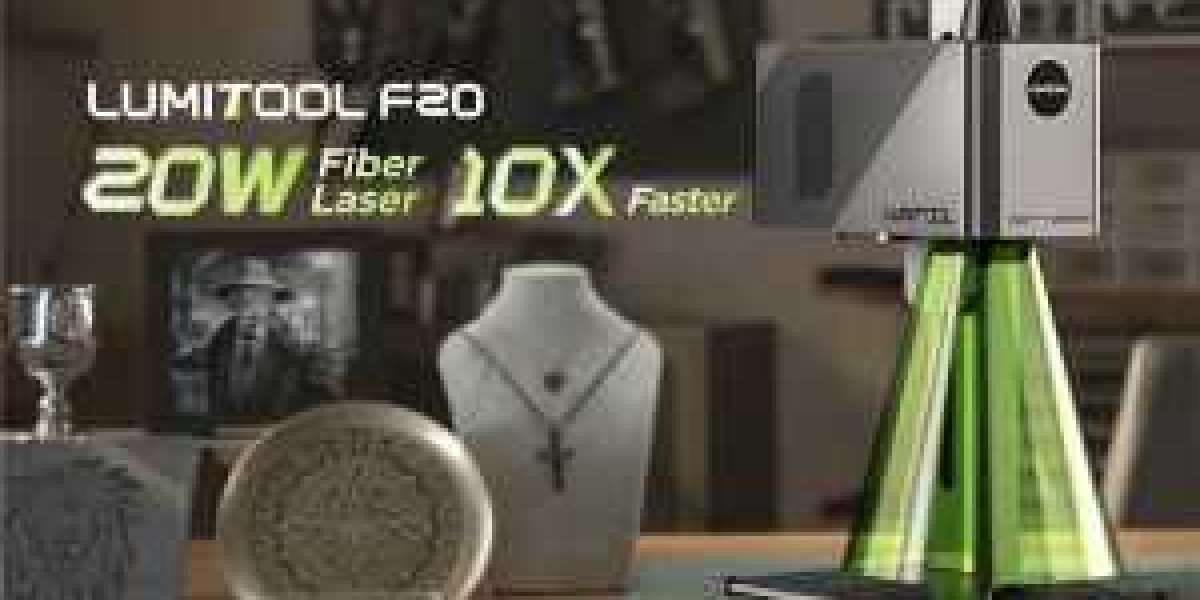

One of the biggest advantages of fiber laser marking is speed. These machines can complete jobs up to ten times faster than conventional engraving tools. Whether you're producing small batches of customized merchandise or large quantities of industrial parts, the efficiency gains translate directly into increased productivity and profit. Moreover, the cutting-edge technology allows for seamless conversion between handheld and desktop modes, giving manufacturers unparalleled flexibility in how they approach different projects.

Precision isn’t just about sharp lines and clear labels — it's also about consistency. A fiber laser marking machine ensures every product carries the same high-quality marking, no matter the material or surface texture. From intricate logos and serial numbers to decorative engravings and personalized designs, the uniformity is unmatched. This reliability is essential for industries like automotive, electronics, medical devices, and premium goods where even the smallest marking errors can have serious consequences.

Another standout feature is versatility. These machines handle over 100 types of materials and provide multi-angle engraving capabilities, including rotary options for cylindrical objects. Whether you’re working with metal jewelry, wooden home décor, medical devices, or plastic components, laser marking technology adapts to your needs. It also integrates easily with smart apps for remote control, design uploading, and monitoring — making it perfect for both small boutiques and large-scale production facilities.

Maintenance is minimal too. Since the process is non-contact, there’s virtually no wear and tear on the device, and no consumables like ink or engraving tools are needed. With an expected life span of over 100,000 hours, a fiber laser marking machine is a cost-effective investment that lowers operational expenses over time.

Safety is also built into the design. Dual-light focusing systems, enclosed laser heads, and protective gear recommendations make operation safer and more precise than ever. These precautions ensure that even advanced marking technologies remain accessible to small businesses and artisans.

In short, adopting a fiber laser marking machine is more than just upgrading your equipment — it's upgrading your entire approach to manufacturing, customization, and branding. If you’re ready to elevate efficiency, precision, and product quality, it’s time to explore why this technology is a must-have for the future.