Maintenance is one of the most significant ongoing expenses for organizations that manage complex electrical, AV, or security systems. Unexpected failures, troubleshooting delays, and human errors can quickly escalate costs and disrupt operations. One of the most effective ways to reduce maintenance expenses is through the use of accurate and well-maintained wiring diagrams. Modern Wiring Diagram Software provides a powerful solution by automating documentation, improving system visibility, and streamlining maintenance workflows. By leveraging these tools, companies can not only enhance system reliability but also significantly cut down on maintenance costs.

The Cost Challenges of Maintenance

Maintaining complex systems is often more expensive than initial installation. Several factors contribute to rising maintenance costs:

Troubleshooting Delays: Technicians spend significant time tracing connections and identifying issues in poorly documented systems.

Human Errors: Manual wiring and inconsistent documentation can lead to repeated mistakes during repairs.

Downtime Costs: System downtime, whether in AV, renewable energy, or access control systems, directly affects productivity and revenue.

Inefficient Updates: When system modifications are made without updated diagrams, future maintenance becomes more complicated and expensive.

Reducing these costs requires better system visibility, accurate documentation, and streamlined workflows. This is where Wiring Diagram Software plays a crucial role.

How Wiring Diagram Software Reduces Maintenance Costs

Wiring Diagram Software improves maintenance efficiency in several ways, ultimately lowering expenses.

1. Accurate and Up-to-Date Documentation

One of the primary benefits of wiring diagram software is the ability to maintain accurate, up-to-date diagrams. When system changes occur, such as adding new devices, rerouting connections, or replacing components, diagrams can be updated in real-time. Accurate documentation reduces the time technicians spend tracing circuits, locating components, and identifying faults, which directly lowers labor costs.

2. Streamlined Troubleshooting

With automated wiring diagrams, technicians can quickly identify problem areas. The software visually maps connections and highlights key components, making it easier to isolate issues. By reducing trial-and-error troubleshooting, maintenance teams can resolve problems faster and minimize downtime, translating into cost savings.

3. Predictive Maintenance

Some advanced Wiring Diagram Software integrates with monitoring and IoT systems to provide predictive maintenance insights. By analyzing wiring paths and system performance, the software can flag potential issues before they escalate into failures. Predictive alerts allow maintenance teams to take action proactively, avoiding expensive repairs and preventing operational disruptions.

4. Consistency Across Multiple Sites

For organizations with multiple locations, wiring diagram software ensures consistent documentation across all sites. Standardized diagrams reduce errors caused by differing wiring practices or incomplete records. Maintenance teams can apply proven procedures across locations, which minimizes repeat errors and associated costs.

5. Training and Knowledge Transfer

Wiring diagram software also serves as a training tool for new technicians. Well-documented diagrams make it easier for staff to understand complex systems, reducing the learning curve and the likelihood of mistakes. Fewer errors during maintenance translate into fewer repair costs and improved system longevity.

6. Reduced Downtime

By enabling faster troubleshooting and preventive maintenance, wiring diagram software reduces system downtime. This is especially critical in industries where downtime is costly, such as manufacturing plants, corporate AV systems, or renewable energy installations. Reduced downtime means less financial loss and lower indirect maintenance costs.

Real-World Applications

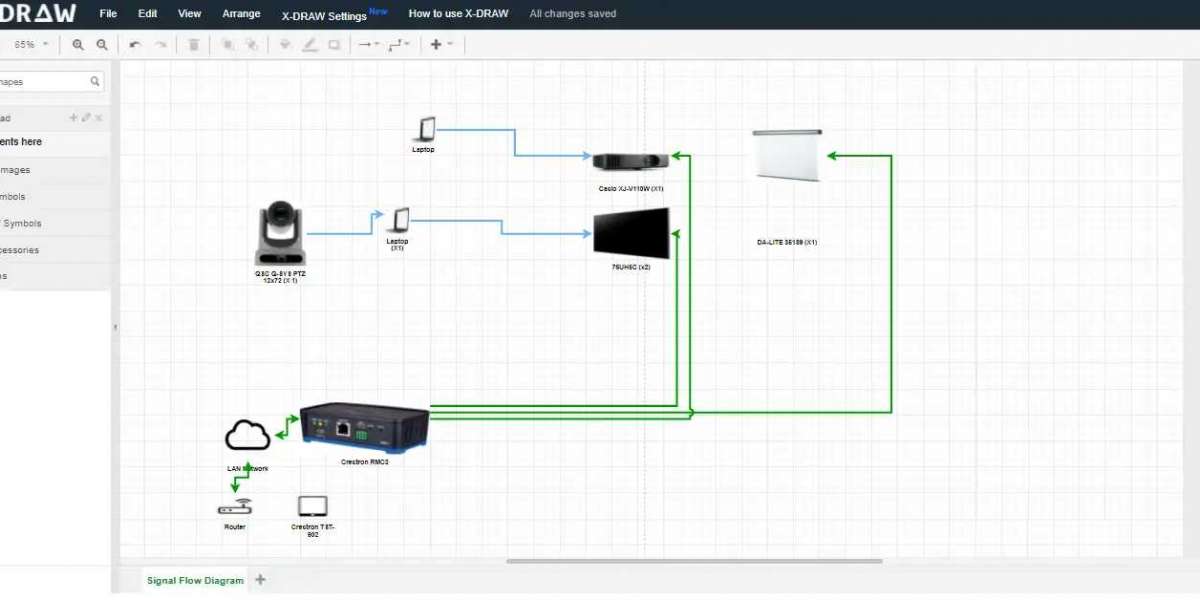

AV and Broadcast Systems

In large AV installations, such as stadiums or conference centers, wiring diagrams help technicians trace speaker connections, video feeds, and control systems quickly. Software-generated diagrams eliminate the need to manually inspect hundreds of cables, reducing labor costs and minimizing downtime during events.

Renewable Energy Installations

Solar farms and wind energy plants involve thousands of interconnected devices. Accurate wiring diagrams allow maintenance teams to identify faulty panels, inverters, or turbines quickly. Predictive alerts and standardized documentation further reduce expensive downtime and repair costs.

Access Control and Security Systems

Multi-site access control systems rely on precise wiring between card readers, controllers, and monitoring devices. Wiring diagram software ensures that technicians can implement updates or troubleshoot issues efficiently. Standardized diagrams reduce errors that can lead to security breaches and costly emergency repairs.

Smart Buildings

Smart buildings integrate AV, lighting, HVAC, and IoT devices. Maintenance requires an understanding of how these systems interact. Wiring diagram software provides a clear visual map of the entire network, enabling maintenance teams to resolve issues quickly and maintain operational efficiency.

XTEN-AV: Driving Maintenance Efficiency

XTEN-AV offers a Wiring Diagram Software platform designed to optimize maintenance workflows. With its advanced automation, cloud access, and real-time updates, XTEN-AV ensures that diagrams are always accurate and accessible to maintenance teams.

Key benefits include:

Automated Diagram Updates: System changes are reflected instantly, reducing manual updates and ensuring technicians always work with current information.

Predictive Maintenance Support: Integration with monitoring systems allows teams to address potential failures before they become costly issues.

Collaboration and Access Control: Teams can access diagrams remotely, comment, and collaborate in real-time, improving efficiency and communication.

Error Detection: Built-in validation tools prevent incorrect connections and reduce repeat maintenance caused by human error.

By adopting XTEN-AV, organizations can minimize maintenance-related expenses while improving system reliability and operational efficiency.

Future Trends

The role of wiring diagram software in maintenance is set to expand as technology advances. AI and machine learning will provide more accurate predictive maintenance, identifying potential wiring faults based on patterns and historical data. Integration with augmented reality will allow technicians to visualize wiring diagrams over physical installations, further reducing troubleshooting time and costs.

As systems become more complex, the value of automated, accurate, and collaborative wiring diagrams will only grow. Organizations that adopt these technologies now will enjoy long-term cost savings and operational advantages.

Conclusion

Maintenance costs can be a significant burden for organizations managing complex electrical, AV, or security systems. Traditional methods of documentation and troubleshooting are slow, error-prone, and costly. Wiring Diagram Software provides a solution by automating diagrams, improving accuracy, enabling predictive maintenance, and facilitating faster troubleshooting.

XTEN-AV leads the industry in providing intelligent Wiring Diagram Software that helps organizations reduce maintenance expenses across project types and scales. By adopting these tools, companies can minimize downtime, prevent costly errors, and ensure that their systems operate efficiently for years to come. In a competitive and technology-driven landscape, investing in wiring diagram software is not just a convenience—it is a strategic step toward lowering maintenance costs and improving overall operational performance.