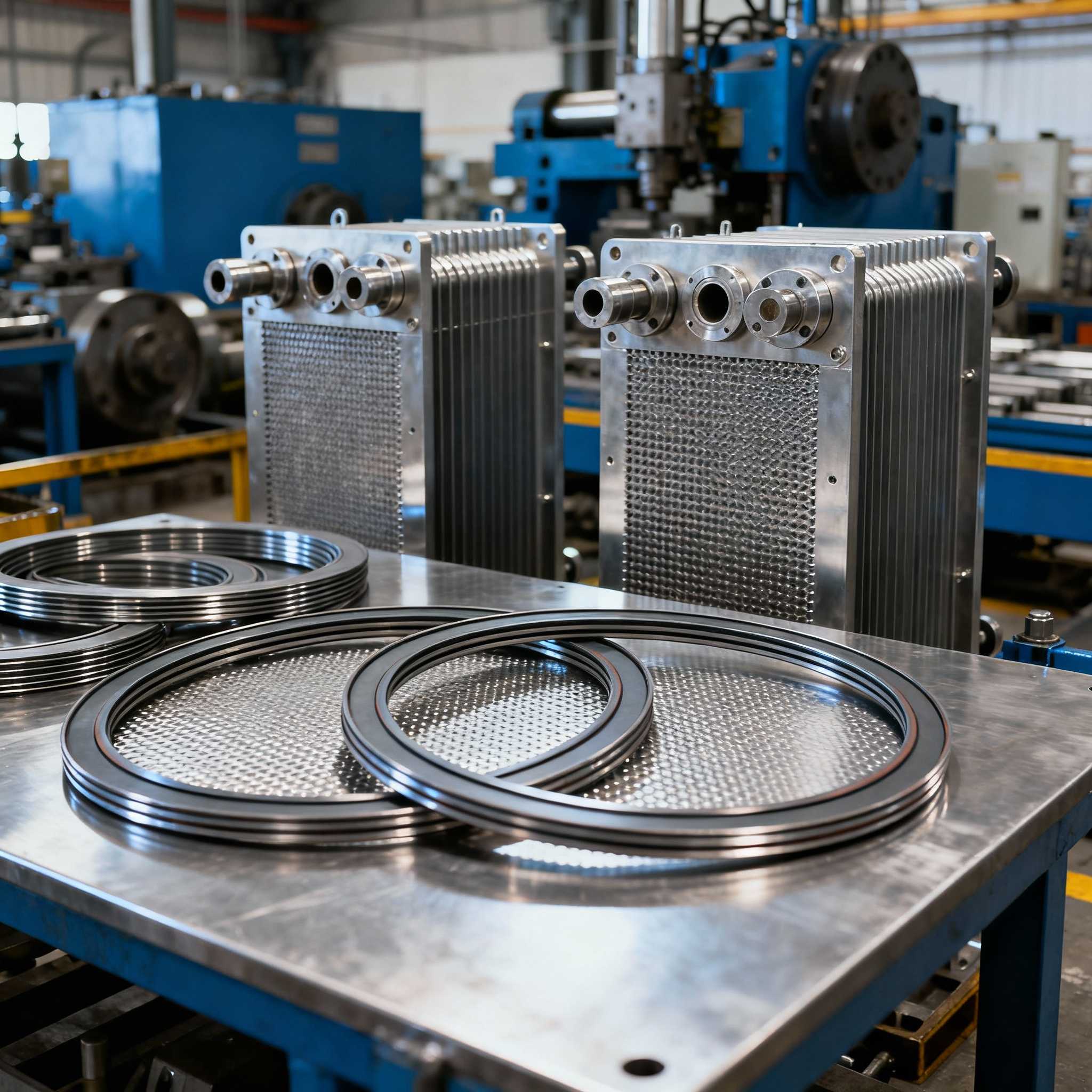

In the world of industrial heat exchangers, maintaining optimal performance is crucial. One of the most important aspects of this maintenance is ensuring the integrity of your Reheat PHE gaskets plates. With SRJ Heatt, a leading name in heat exchanger solutions, you can guarantee top-notch performance, longevity, and thermal efficiency for your systems.

Why Reheat PHE Gaskets Plates Matter

Plate Heat Exchangers (PHEs) rely heavily on the quality of their gaskets and plates. These components ensure the safe transfer of heat between fluids, prevent leaks, and maintain system pressure integrity. Over time, wear and tear can reduce efficiency, leading to higher energy costs and possible system downtime.

By using high-quality Reheat PHE gaskets plates, you can:

Reduce maintenance downtime

Improve thermal performance

Extend the lifespan of your heat exchanger

Ensure leak-free operation

SRJ Heatt offers gaskets and plates that are engineered for durability, corrosion resistance, and precise fit, ensuring your PHE operates at peak performance.

Common Issues with Worn Gaskets Plates

Even a minor defect in a PHE can have significant consequences. Some common issues include:

Leaking gaskets due to thermal cycling or chemical degradation

Plate fouling that reduces heat transfer efficiency

Corrosion from aggressive fluids

Pressure drops due to warped or damaged plates

Timely replacement of Reheat PHE gaskets plates from SRJ Heatt can prevent these problems, keeping your system efficient and reliable.

Benefits of Upgrading to SRJ Heatt

Choosing SRJ Heatt products means investing in industrial-grade reliability. Their custom-engineered gaskets are designed to withstand extreme temperatures, pressures, and chemical exposure. Additionally, SRJ Heatt’s plates are precision-engineered to ensure optimal fluid flow, maximizing heat transfer efficiency.

Other advantages include:

Extended equipment lifespan

Reduced maintenance frequency

Enhanced operational safety

Compliance with industry standards

Tips for Maintaining Your PHE

To maximize the life of your Reheat PHE gaskets plates, regular maintenance is key:

Inspect gaskets for wear or cracks during scheduled downtime.

Clean plates to prevent fouling and scaling.

Check for signs of corrosion or pitting.

Ensure proper torque when assembling the PHE to prevent leaks.

By combining high-quality SRJ Heatt components with proactive maintenance, you can ensure your system runs efficiently for years.

Conclusion

Investing in Reheat PHE gaskets plates from SRJ Heatt is more than just a replacement—it's a step toward operational excellence. By prioritizing reliable gaskets, durable plates, and proactive maintenance, you safeguard your heat exchanger’s performance, minimize downtime, and maximize energy efficiency.

For industries that rely on consistent heat exchange, SRJ Heatt remains the trusted partner for quality and reliability in every gasket and plate.