In the world of industrial thermal management , plate heat exchangers (PHE) stand out as efficient solutions for heat transfer across sectors like food processing, HVAC, and chemical manufacturing. At the heart of these systems lie critical components: GEA (Kelvion) PHE gaskets plates . As a leading supplier, SRJ Heatt specializes in providing top-tier OEM-compatible spares that ensure seamless operation and longevity. This guide dives deep into these essentials, exploring their design, benefits, and maintenance to help you optimize your energy-efficient systems .

The Fundamentals of GEA (Kelvion) PHE Design

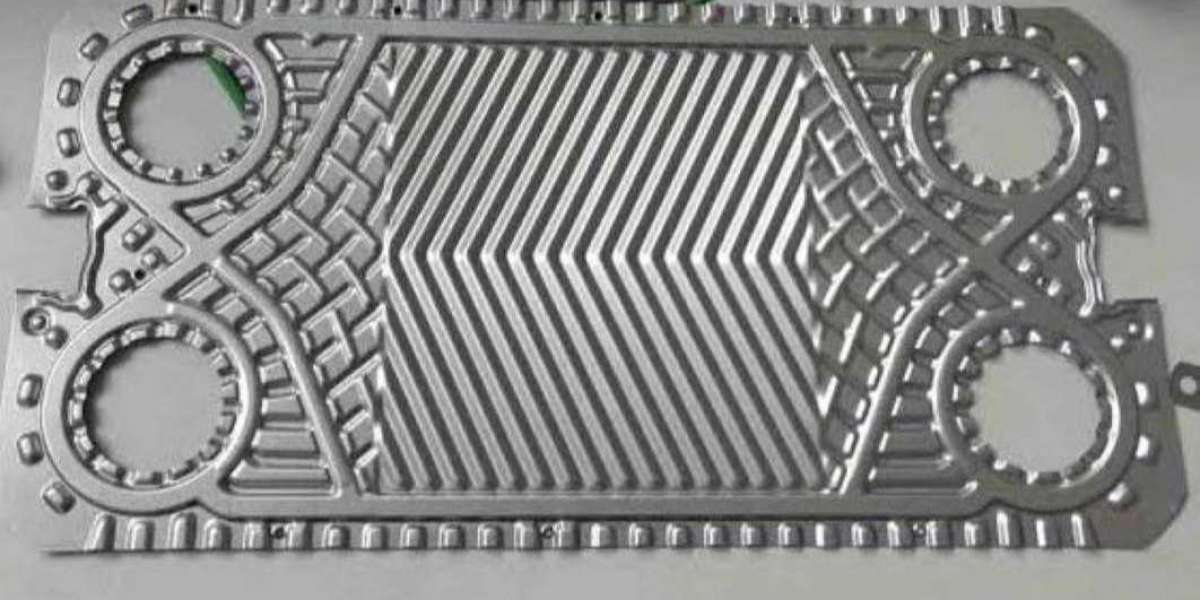

GEA (Kelvion) , a powerhouse in heat exchanger technology , has pioneered gasketed plate heat exchangers (GPHE) that deliver superior thermal performance . These units feature stacked corrugated plates sealed by precision-engineered gaskets , creating alternating channels for hot and cold fluids. The Kelvion EcoFlex and NT series , for instance, boast innovative chevron patterns that enhance turbulent flow , boosting heat recovery by up to 95% compared to traditional shell-and-tube designs.

What sets GEA (Kelvion) PHE gaskets plates apart is their adaptability. Plates are crafted from durable materials like stainless steel or titanium, resisting corrosion in harsh environments. Gaskets, typically made from elastomeric compounds such as NBR or EPDM, provide leak-proof sealing while accommodating thermal expansion. At SRJ Heatt, we stock a full range of these PHE components, ensuring quick delivery for minimal downtime in your industrial cooling setups.

Crucial Role of Gaskets in PHE Efficiency

No discussion of GEA (Kelvion) PHE gaskets plates is complete without highlighting the gaskets' pivotal function. These sealing elements prevent cross-contamination, directing fluids through designated paths for optimal heat exchange. In VARITHERM models, clip-on or glue-free gasket designs simplify retrofits, reducing labor costs by 30%.

Common challenges include degradation from high temperatures or aggressive media, leading to leaks that compromise system integrity. Regular inspection of channel gaskets and end plate seals is vital. SRJ Heatt recommends preventive maintenance kits tailored for Kelvion FA series, incorporating FDA-approved materials for sanitary applications in dairy or pharmaceuticals. By choosing high-grade PHE seals, industries can achieve sustainable operations, cutting energy use and extending equipment life.

Maximizing Performance with Quality Plates

The plates in GEA (Kelvion) PHE gaskets plates are the workhorses of fluid separation. Their pressed patterns—wide-gap for viscous fluids or narrow for high-pressure duties—promote intensive mixing, elevating overall heat transfer coefficients. For example, LWC plates excel in compact installations, offering up to 20% space savings over competitors.

Material selection is key: 316L stainless for general use, or Hastelloy for corrosive streams. SRJ Heatt sources authentic Kelvion plates that match original specs, ensuring compatibility with existing frames. Upgrading to advanced free-flow plates can slash fouling risks, maintaining peak thermal efficiency in HVAC heat recovery or process heating scenarios.

Maintenance Best Practices for Longevity

To sustain GEA (Kelvion) PHE reliability, proactive care of gaskets plates is non-negotiable. Start with annual disassembly to check for wear—look for cracks in elastomer gaskets or pitting on heat transfer surfaces. Cleaning protocols using non-abrasive solutions preserve corrugation integrity, while proper reassembly prevents misalignment.

When replacement is due, opt for compatible spares from trusted providers like SRJ Heatt. Our gasket replacement services include on-site audits, guaranteeing a perfect fit for EcoFlex or NT-U configurations. This approach not only averts costly failures but also aligns with green standards, reducing carbon footprints through enhanced energy conservation.

In troubleshooting, monitor pressure drops as early indicators of gasket failure. For plate fouling, chemical descaling restores efficiency without disassembly. SRJ Heatt's expertise ensures your industrial heat exchangers run flawlessly, supporting scalable operations.

Why SRJ Heatt is Your Go-To for GEA (Kelvion) Solutions

At SRJ Heatt, we're more than suppliers—we're partners in thermal optimization. Our inventory of GEA (Kelvion) PHE gaskets plates covers every series, from standard duty to high-pressure variants, all backed by rigorous quality checks. Whether you're retrofitting a brazed PHE alternative or expanding district heating networks, our solutions deliver unmatched cost-effectiveness.

We prioritize customer-centric service, offering customization for unique fluid handling needs. Join countless clients who've boosted operational uptime by 25% with our PHE spare parts. Contact SRJ Heatt today for a free consultation on enhancing your heat exchanger maintenance strategy.

Conclusion: Elevate Your Systems with Precision Components

Investing in superior GEA (Kelvion) PHE gaskets plates translates to reliable, efficient heat management that drives profitability. From sealing innovation to plate durability , these elements underpin versatile applications in modern industry. Partner with SRJ Heatt to access premium OEM gaskets , expert guidance, and sustainable thermal solutions . Ready to upgrade? Reach out now and transform your PHE performance .