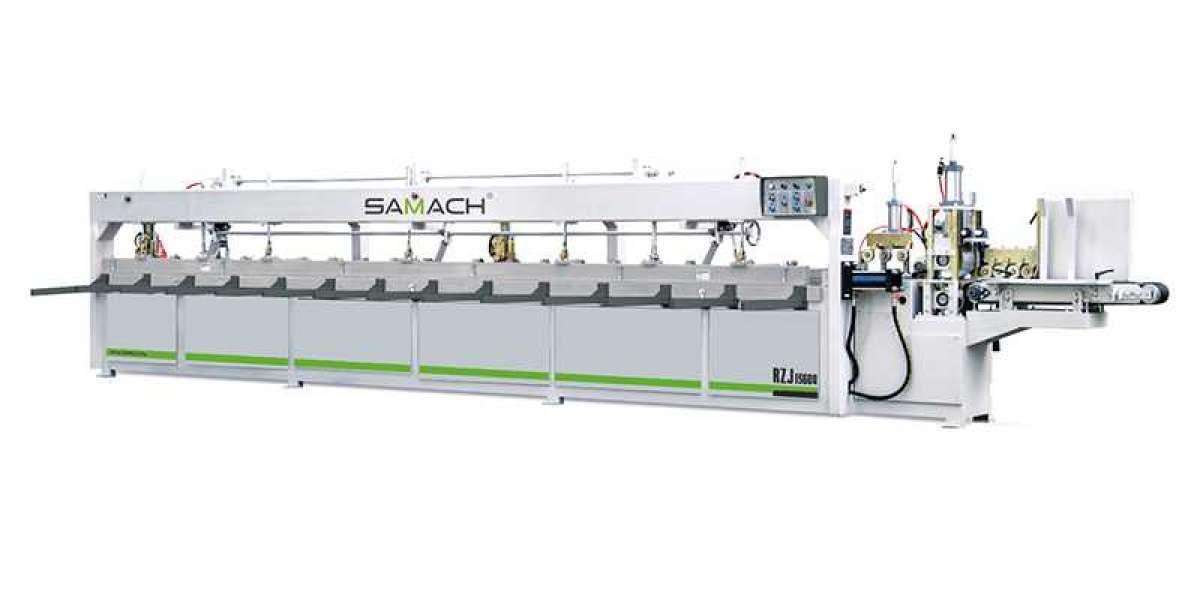

A Finger Joint Machine is a specialized tool in woodworking that creates durable joints by cutting wood ends into finger-like shapes that interlock perfectly. This type of joint is widely used in the production of furniture, doors, window frames, and structural panels, where both strength and precision are essential. Its unique design makes it more reliable than simple joints and ensures long-term durability.

One of the main advantages of using a finger joint machine is its ability to utilize leftover or shorter wooden pieces by combining them into longer boards. This not only reduces material wastage but also lowers costs for manufacturers. The larger glue surface created by the finger pattern ensures strong adhesion, which results in highly stable and long-lasting connections.

Modern finger joint machines are built with advanced features such as automatic feeding, computer-guided accuracy, and high-speed cutting systems. These innovations allow businesses to save time, reduce errors, and maintain consistent quality across large production runs. They also work with both hardwood and softwood, making them highly versatile.

In summary, finger joint machine is essential for woodworking companies looking to enhance productivity, sustainability, and product strength. By investing in this technology, manufacturers can achieve efficient material usage, superior joints, and a competitive edge in the m

arket.