Dental CAD/CAM Milling Machines: Revolutionizing Prosthetics with Precision and Speed in India

The dental industry in India is experiencing a significant digital transformation, with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) milling machines emerging as pivotal tools. These advanced machines are revolutionizing the fabrication of dental prosthetics, offering unprecedented levels of precision, efficiency, and patient satisfaction, and are increasingly becoming a cornerstone of modern dental practices and laboratories across the country.

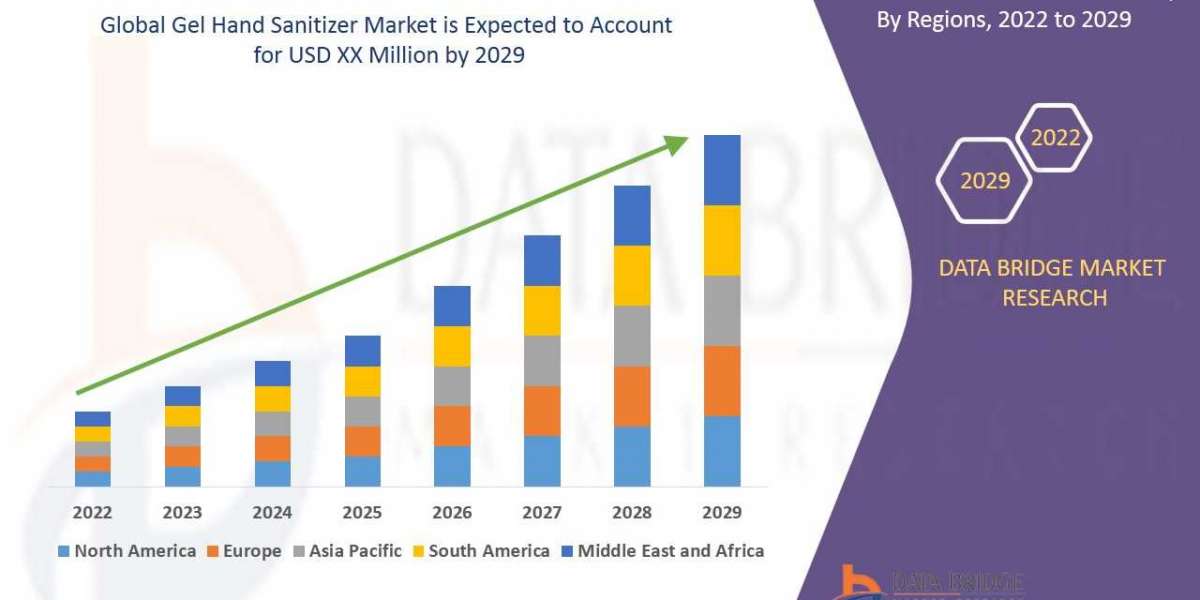

The India dental milling machines market is witnessing robust growth, reaching an estimated USD 97.02 million in 2024 and projected to reach USD 197.40 million by 2033, with a CAGR of 7.70% during 2025-2033. This surge is primarily driven by the rising adoption of digital dentistry, escalating demand for highly accurate dental restorations, and the growth of dental tourism in India.

Key Innovations and Trends in the Indian Market:

- Digital Workflow Integration: The most significant impact of CAD/CAM milling machines is their seamless integration into a fully digital workflow. This process begins with intraoral scanners capturing precise 3D digital impressions of a patient's mouth, eliminating the need for uncomfortable traditional molds. The digital data is then used by CAD software to design custom restorations, which are subsequently milled with utmost accuracy by CAM machines. This streamlined process is significantly reducing turnaround times, often enabling same-day restorations for crowns, bridges, and veneers.

- Precision and Accuracy: Modern dental milling machines, particularly 5-axis models, offer superior flexibility and precision, allowing for the creation of complex restorations with intricate designs and precise margins. This level of accuracy is difficult to achieve manually, leading to better-fitting, more durable, and aesthetically pleasing prosthetics. Companies like Amann Girrbach recently launched their "Ceramill Matron," a fifth-generation milling machine emphasizing maximum precision and surface quality.

- Chairside vs. Labside Milling: The market is seeing growth in both chairside (in-office) CAD/CAM systems and larger labside (dental laboratory) machines. Chairside units empower dentists to design and fabricate restorations on-site, offering immediate results and enhancing patient convenience. Labside machines, on the other hand, cater to higher volume production and more complex restorations, serving multiple clinics.

- Material Versatility: Advances in milling technology allow these machines to process a wide range of materials, including ceramics (zirconia, lithium disilicate, glass ceramics), composites, and even metals like titanium and cobalt-chromium. This versatility enables dentists to choose the optimal material for each patient's specific needs, balancing aesthetics, strength, and biocompatibility.

- AI and Machine Learning Integration: The future of dental milling is increasingly intertwined with Artificial Intelligence (AI). AI algorithms are being integrated into CAD/CAM software to enhance design algorithms, predict optimal restoration shapes, and further streamline workflows, promising even greater efficiency and precision.

- Growing Adoption in India: Cities like Delhi-NCR, Mumbai, Bengaluru, Chennai, Kochi, and Hyderabad are witnessing widespread adoption of CAD/CAM dentistry. This is driven by increased patient awareness of cosmetic dental procedures, the demand for quick and accurate solutions, and investments by dental clinics and laboratories in advanced technology. Organizations like the Dental Council of India have noted increased patient demand for precise and personalized dental solutions.

- Addressing Dental Disorders: With a rising prevalence of dental disorders, including dental caries and edentulism, and a growing geriatric population, the demand for improved restorative and prosthetic services is stimulating the use of sophisticated dental milling machines across India.

While the initial investment in CAD/CAM milling machines can be substantial, the long-term benefits in terms of efficiency, patient satisfaction, reduced material waste, and improved clinical outcomes are driving their rapid integration into India's dental landscape. As technology continues to evolve and become more accessible, dental CAD/CAM milling machines are set to play an even more crucial role in delivering high-quality, modern dental care across the nation.