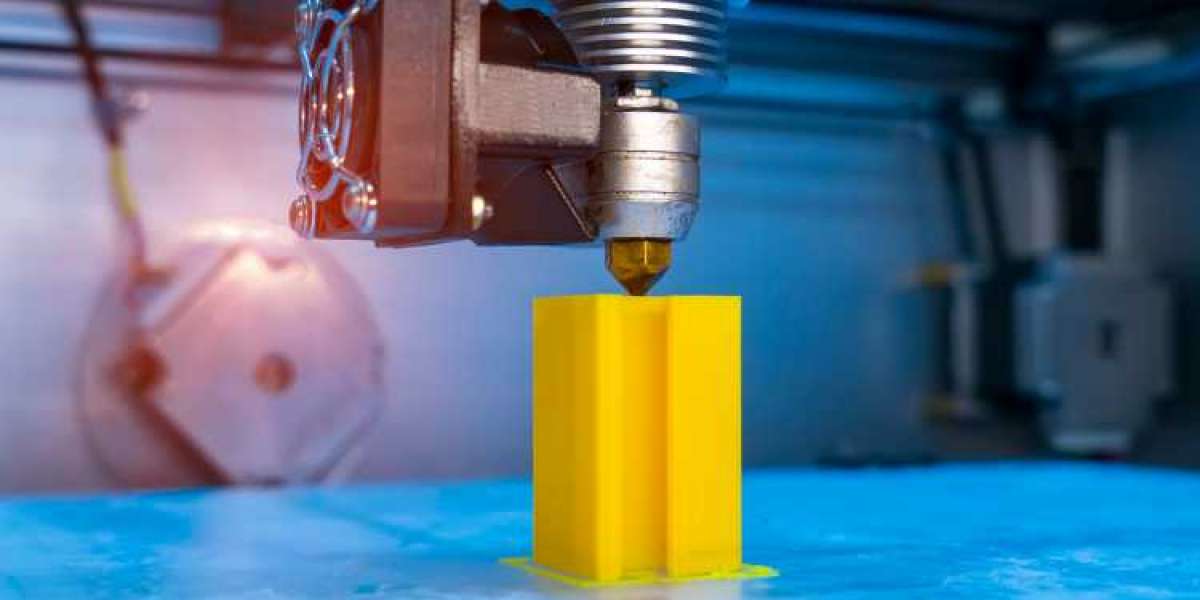

Injection molding process is the highly accurate manufacturing system which Norck provides for the production of good quality plastic components in large numbers. Plastic pellets are melted and then injected into a mold that has been custom designed for this purpose and is held on very high pressures. After the plastic cools and solidifies, the mold simply opens to give the finished part. Norck uses advanced machinery and engineering skills to build tight tolerances with consistent part quality, economically from prototyping to full production runs. They specialize in many thermoplastics and offer material selection recommendations based on strength, flexibility, and durability. Injection molding services at Norck are used in the automotive, medical, consumer goods, and electronics industries. Norck prides itself on innovation, speed, and quality on the very shortest lead times to ensure their customers can get to market fastest. Their services also extend into mold design, rapid tooling, and post-processing, presenting clients with a complete end-to-end manufacturing solution.

Buscar

entradas populares

-

12 najkrajších vianočných rozprávok a komédií, ktoré by ste si s deťmi mali pozrieť

Por Martin Zich

12 najkrajších vianočných rozprávok a komédií, ktoré by ste si s deťmi mali pozrieť

Por Martin Zich -

Nastavenie kategorii zobrazovania (zapnutie XXX a Software)

Por Martin Zich

Nastavenie kategorii zobrazovania (zapnutie XXX a Software)

Por Martin Zich -

Community Hobbies in Dubai Meetups for Every Interest and Passion

Por jukulim lao

Community Hobbies in Dubai Meetups for Every Interest and Passion

Por jukulim lao -

Strážci Galaxie celá filmová séria v jednom blogu (2014-2023)

Por Martin Zich

Strážci Galaxie celá filmová séria v jednom blogu (2014-2023)

Por Martin Zich -

gates of olympus game

Por sasafarben

gates of olympus game

Por sasafarben

Categorías

- Automóviles y Vehículos

- Negocios y Oportunidades

- Economía y Comercio

- Educación

- Entretenimiento

- Cine y Animación

- Juego de azar

- Historia y Datos

- Estilos de vida

- Servicios

- Noticias y Política

- Pueblos y Naciones

- Animales y mascotas

- Lugares y Regiones

- Ciencia y Tecnología

- Deporte

- Viajes y Eventos

- Music

- Otro