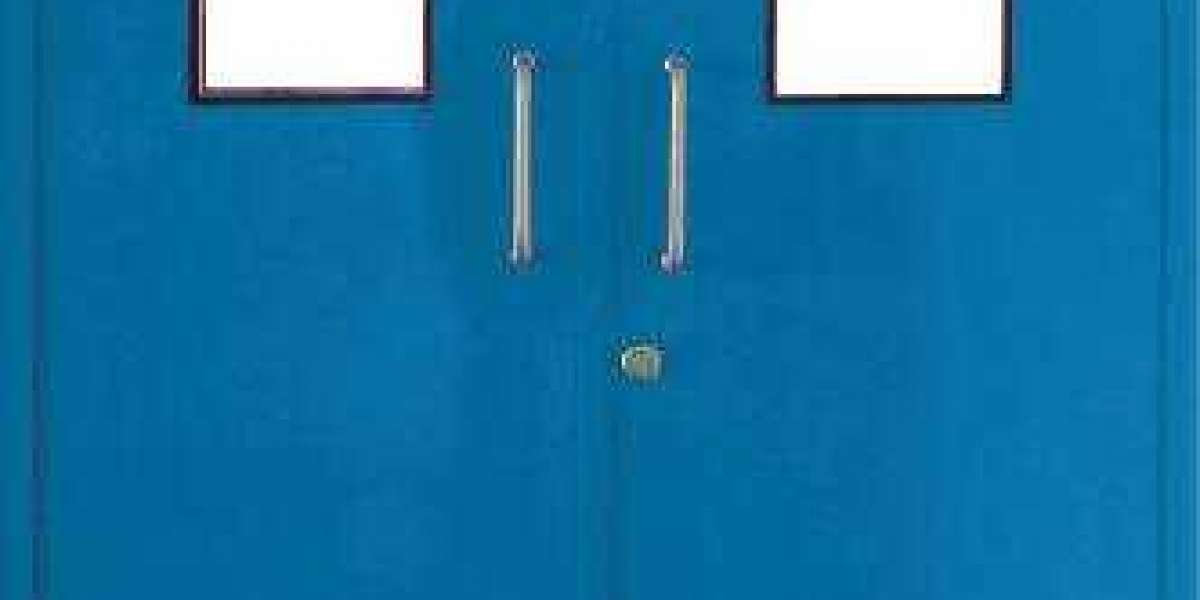

For facilities requiring strict contamination control, yd-purification provides advanced Clean Room Door solutions engineered to meet demanding standards. These doors are essential components in laboratories, pharmaceutical production sites, and other sterile environments where maintaining an uncontaminated atmosphere is crucial.

The design focuses on sealing efficiency and durability. Manufactured from high-quality materials, the doors ensure airtight barriers that prevent particle infiltration and maintain pressure differentials. Smooth surfaces reduce contamination risks and facilitate routine cleaning procedures, supporting operational hygiene. This combination of design and material choice enables these doors to withstand harsh cleaning agents commonly used in controlled environments, preserving integrity throughout extended use.

Options include manual and automated mechanisms tailored to operational needs. Automatic doors offer convenience and reduce human contact, minimizing contamination sources. Both types integrate seamlessly with cleanroom walls, maintaining consistent airflow patterns and preserving environmental integrity. The automated systems incorporate advanced sensors and controls to ensure smooth, reliable operation, adapting to the dynamic needs of busy facilities.

Installation flexibility allows adaptation to various architectural designs. Custom dimensions and finishes ensure that doors fit unique layout requirements without compromising performance. Special glazing options provide visibility while preserving airtightness, enabling monitoring without compromising safety. These glazing options can include anti-reflective coatings or reinforced safety glass to meet specific project requirements.

Every unit undergoes rigorous quality inspections before shipment, assuring compliance with industry standards. Protective packaging minimizes transit damage, enabling straightforward installation and long-term reliability. Comprehensive documentation and installation guidance accompany each product, streamlining the setup process and helping clients meet cleanroom certification criteria.

The combination of precise engineering and thoughtful design results in doors that contribute to workflow efficiency, safety, and contamination control. As an integral part of cleanroom infrastructure, they support strict regulatory compliance and smooth operational processes. By choosing these doors, facilities gain reliable access points that enhance environmental control and reduce downtime caused by maintenance or operational interruptions.

In addition, yd-purification provides technical consultation and after-sales support to ensure client satisfaction and optimal product performance throughout the lifecycle. This commitment to service complements the product quality, making yd-purification a trusted partner in cleanroom infrastructure solutions.

Explore the full range of solutions crafted for demanding environments by visiting www.yd-purification.com and find products tailored to your facility’s needs.