Pipelines carry vital resources, cables transmit essential data, and conduits house utilities that power modern life. However, this hidden world is vulnerable to accidental damage during excavation, construction, or even routine maintenance. The consequences of such damage can range from minor disruptions to catastrophic failures, posing significant risks to safety and the environment. This is where the unsung hero, the Warning mat in pipeline manufacturers in Ahmedabadsteps into the spotlight, acting as a crucial safeguard against such calamities.

This unassuming, often brightly colored, mesh is meticulously laid above buried utilities, providing a tangible warning to excavators before they inadvertently strike a pipeline or cable. Its presence acts as a physical and visual deterrent, signaling the presence of critical infrastructure below. The composition of these meshes varies, often utilizing durable polymers like polypropylene or polyethylene, designed to withstand the rigors of burial and resist degradation over time. The choice of material is critical, ensuring longevity and consistent performance in diverse soil conditions. The mesh is typically manufactured in a grid-like pattern, allowing for flexibility and adaptability to various trench widths and depths.

The Art of Detection: Visual and Tactile Alerts

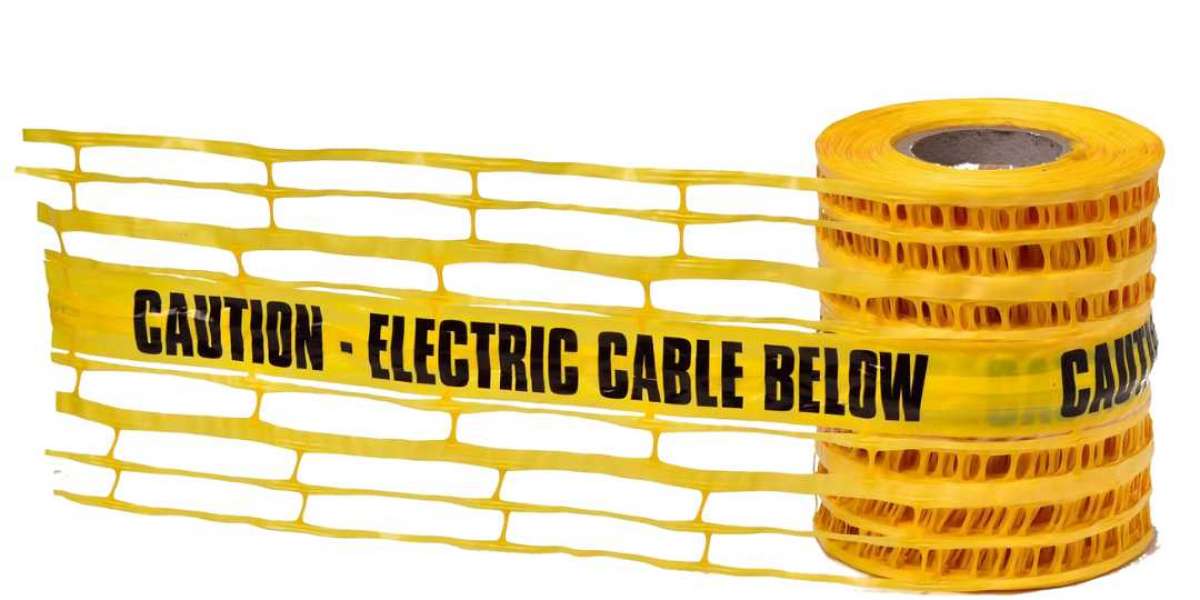

The effectiveness of an underground warning mesh lies in its ability to provide clear and immediate warning. The vibrant colors, such as bright yellow, orange, or red, serve as a stark visual contrast to the surrounding soil, instantly alerting workers to the potential hazard. Furthermore, the mesh's physical texture provides a tactile warning, allowing excavators to feel the presence of the protective layer before making contact with the underlying utility. This dual-layered approach, combining visual and tactile cues, significantly reduces the risk of accidental damage.

The application of underground warning mesh extends across various industries, including oil and gas, telecommunications, water and sewage, and electricity. In the oil and gas sector, these meshes protect pipelines carrying flammable and hazardous substances, preventing potentially devastating leaks and explosions. In telecommunications, they safeguard fiber optic cables, ensuring uninterrupted data transmission. In water and sewage systems, they protect pipelines that deliver clean water and remove waste, maintaining public health and sanitation. And in the electrical sector, they protect high-voltage cables, preventing power outages and electrical hazards.

Regional Hubs and Global Reach: The Role of Manufacturers and Exporters

The manufacturing and distribution of underground warning mesh are critical components of ensuring infrastructure safety. Specialized manufacturers, often located in industrial hubs, play a pivotal role in producing high-quality meshes that meet stringent industry standards. In regions like Ahmedabad, India, specialized manufacturers are at the forefront of producing these vital safety products. Specifically, the "Warning mat in pipeline manufacturers in Ahmedabad" are a vital part of the supply chain.

The export of these safety products is equally essential, ensuring that underground infrastructure around the globe is adequately protected. Companies specializing in Warning tape for underground cable exporters in Indiaand "Warning tape for underground cable exporters in Ahmedabad" contribute significantly to global infrastructure safety. The quality of exported products is paramount, as they must withstand diverse environmental conditions and meet the specific requirements of different regions.

Beyond the Mesh: The Importance of Complementary Measures

While underground warning mesh is a crucial safety measure, it is often used in conjunction with other protective technologies. Warning tapes, for example, are frequently laid alongside the mesh, providing additional visual warnings and often bearing printed messages indicating the type of utility below. These tapes are designed to be durable and weather-resistant, ensuring long-term visibility and effectiveness.

Furthermore, advancements in technology have led to the development of electronic marking systems, which provide precise location data for buried utilities. These systems utilize radio frequency identification (RFID) tags or other electronic markers that can be detected using specialized equipment. While electronic marking systems offer enhanced accuracy, the simplicity and reliability of underground warning mesh continue to make it an indispensable safety tool.

The Future of Underground Safety: Innovation and Adaptation

As infrastructure continues to expand and evolve, the demand for effective underground safety solutions will only increase. Ongoing research and development are focused on enhancing the performance and durability of warning meshes, exploring new materials, and improving detection technologies. The integration of smart materials and sensors into warning meshes is also being explored, potentially providing real-time monitoring of underground conditions and alerting authorities to potential hazards.

The importance of the invisible protector is growing, and its necessity is unquestionable.

Conclusion

The Warning tape for underground cable exporters in Ahmedabadthough often unseen, plays a vital role in safeguarding subterranean infrastructure. Its simple yet effective design, coupled with its durability and reliability, makes it an indispensable tool for preventing accidental damage and ensuring public safety. As infrastructure continues to expand, the demand for these protective measures will only grow, driving innovation and development in this critical field.

Frequently Asked Questions

- Q: What is the average lifespan of an underground warning mesh?

A: The lifespan of an underground warning mesh depends on the material used and the soil conditions. Typically, high-quality meshes made from durable polymers like polyethylene can last for several decades, often exceeding the lifespan of the buried utilities they protect. Proper installation and soil compaction also contribute to longevity. - Q: Can underground warning mesh be used in all soil types?

A: Yes, underground warning mesh is designed to be versatile and adaptable to various soil types, including sandy, clay, and rocky soils. However, it is essential to select a mesh material that is compatible with the specific soil conditions to ensure long-term durability and performance. - Q: How deep should an underground warning mesh be installed above a buried utility?

A: The installation depth of an underground warning mesh varies depending on local regulations and industry standards. Generally, it is recommended to install the mesh at a depth that provides sufficient warning before reaching the buried utility, typically around 30 to 60 centimeters above the pipeline or cable. This depth allows for clear visual