Polypropylene Sheets Manufacturers in Gujarat are versatile materials with a wide range of applications across various industries. From packaging to construction, these sheets offer durability, flexibility, and affordability. In this article, we'll delve into the world of PP sheets, exploring their uses, benefits, and answering common questions about this popular material.

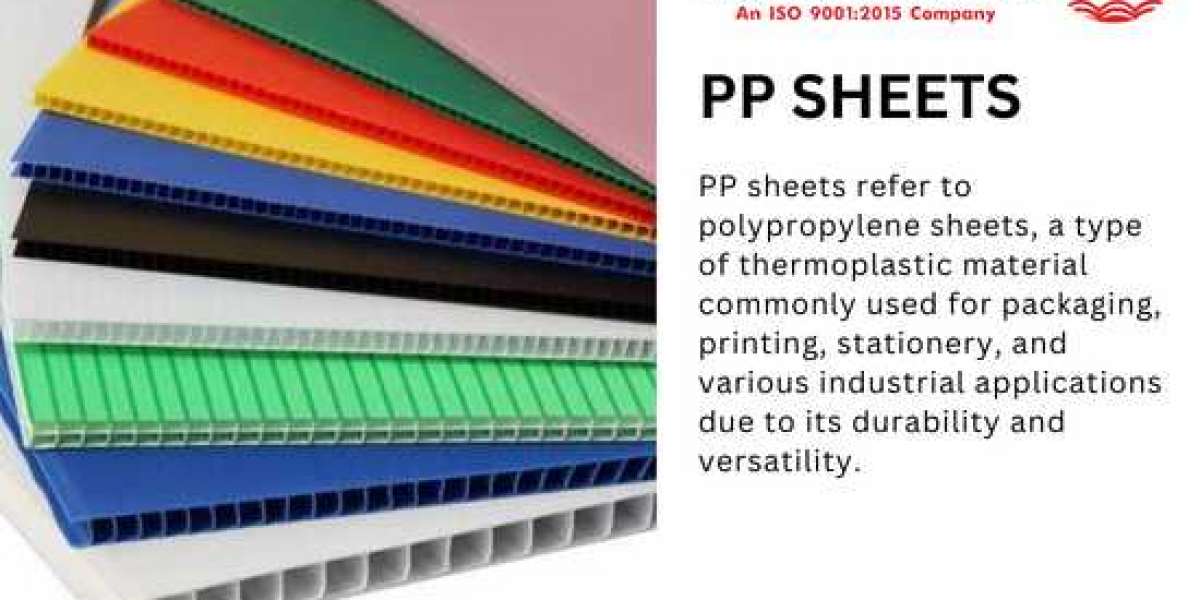

What are PP Sheets?

PP sheets, also known as polypropylene sheets, are thermoplastic polymers made from propylene monomers. These sheets are manufactured through a process of extrusion or molding, resulting in a lightweight yet durable material with excellent chemical resistance and moisture barrier properties.

Uses of PP Sheets:

Packaging: PP Sheet For Wall Suppliers in India are widely used in packaging applications due to their durability and ability to resist tears and punctures. They are commonly used for making food containers, blister packs, and clamshell packaging.

Graphic Arts: PP sheets are popular in the graphic arts industry for applications such as signage, displays, and banners. Their smooth surface allows for high-quality printing, making them ideal for advertising purposes.

Stationery Products: PP sheets are used to create durable stationery products such as folders, binders, and dividers. Their resistance to water and tearing makes them suitable for everyday office use.

Construction: In the construction industry, PP sheets find applications in areas such as roofing, wall cladding, and insulation. Their lightweight nature and resistance to weathering make them ideal for outdoor use.

Automotive: PP sheets are used in automotive interiors for components such as door panels, dashboard trims, and seat backs. They offer a combination of strength, flexibility, and aesthetics.

Benefits of PP Sheets:

Lightweight: PP Sheet Manufacturer in Ahmedabad are lightweight, making them easy to handle and transport. This property is particularly advantageous in applications where weight is a concern, such as packaging and transportation.

Chemical Resistance: PP sheets exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This makes them suitable for use in environments where exposure to chemicals is common, such as laboratories and industrial facilities.

Moisture Barrier: PP sheets have a low moisture absorption rate, making them resistant to moisture and humidity. This property makes them ideal for packaging applications where moisture protection is essential.

Recyclability: PP sheets are recyclable, contributing to environmental sustainability. After use, they can be recycled to produce new products, reducing the need for virgin materials and minimizing waste.

Cost-Effective: PP sheets are cost-effective compared to alternative materials such as PVC or PET. Their affordability makes them an attractive choice for a wide range of applications, helping businesses save on production costs.

Conclusion:

PP sheets are versatile materials with a wide range of applications across various industries. From packaging to construction, these sheets offer numerous benefits including lightweight, chemical resistance, and recyclability. Whether you're looking for durable packaging solutions or weather-resistant building materials, PP sheets are a versatile option worth considering.

FAQs About PP Sheets:

Q1: Are PP sheets suitable for food packaging?

A1: Yes, PP sheets are FDA-approved for food contact and are commonly used in food packaging applications such as containers, trays, and wraps.

Q2: Can PP sheets be recycled?

A2: Yes, PP sheets are recyclable and can be melted down and reused to make new products, contributing to environmental sustainability.

Q3: Are PP sheets heat resistant?

A3: PP sheets have a melting point ranging from 130°C to 171°C, depending on the grade. While they can withstand moderate temperatures, prolonged exposure to high heat can cause deformation.

Q4: Are PP sheets transparent?

A4: PP sheets can be manufactured in both transparent and opaque varieties, depending on the application requirements. Transparent PP sheets are commonly used in packaging and display applications.

Q5: Are PP sheets suitable for outdoor use?

A5: Yes, PP sheets are UV-stable and weather-resistant, making them suitable for outdoor applications such as signage, roofing, and cladding.