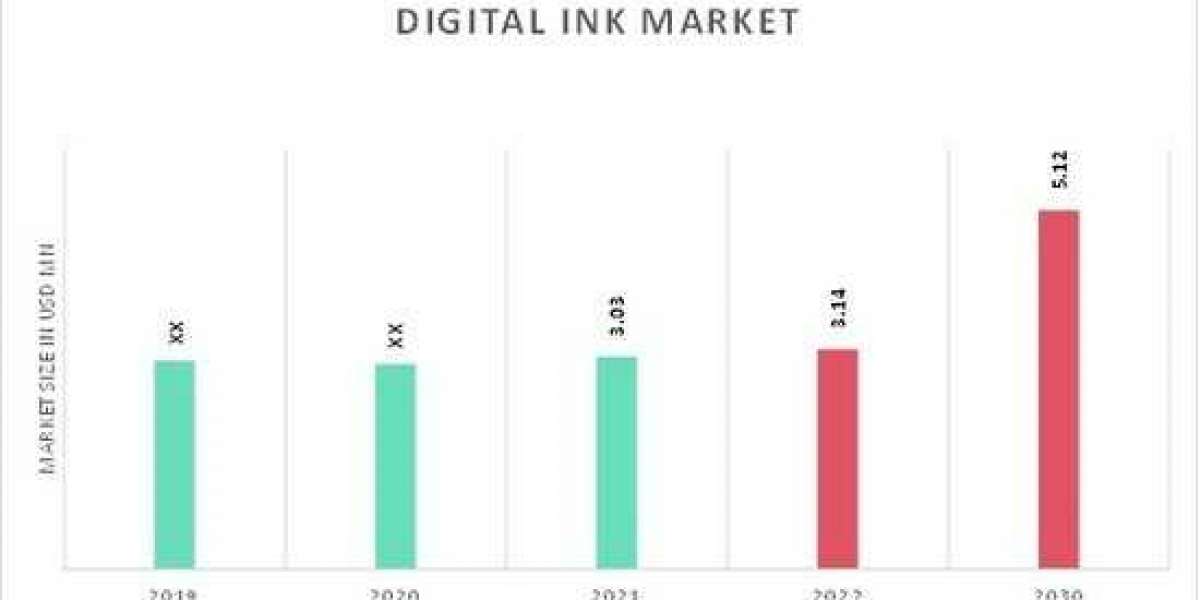

The Digital Ink Market is expanding rapidly as digital printing technologies continue to revolutionize industries such as textiles, packaging, commercial printing, electronics, and even 3D printing. Digital ink refers to specially formulated inks designed for digital printers, capable of producing high-resolution, on-demand prints without the need for traditional printing plates or screens. This innovation has brought greater flexibility, customization, and efficiency to both industrial and consumer applications, fundamentally changing how printing is approached across sectors.

Digital inks are tailored for specific substrates and printing methods, including inkjet and electrophotographic techniques. These inks are typically available in several types such as solvent-based, water-based, UV-cured, and dye-sublimation inks, each suited to different applications and materials. For instance, UV-cured digital inks are widely used in packaging and label printing due to their durability and ability to adhere to non-porous surfaces, while water-based inks are favored in textile printing for their eco-friendly properties and vibrant color output.

The market has seen strong growth due to the rising demand for short-run printing, personalization, and faster turnaround times. Traditional printing methods are being gradually replaced or supplemented by digital alternatives, especially in markets that require high variability and low-volume production. For example, in the fashion and interior design industries, digital textile printing allows for the creation of custom designs in smaller batches without the waste and cost associated with screen printing. This not only saves time but also reduces material waste and energy consumption.

Another significant driver of the digital ink market is the packaging sector. Brands are increasingly using digital printing to create personalized packaging, limited edition designs, and variable data printing for promotions and barcoding. Digital inks enable high-speed production without sacrificing quality, making them ideal for modern supply chains that value agility and responsiveness. The beverage, cosmetics, and food industries, in particular, have embraced digital packaging as a way to enhance customer engagement and brand differentiation.

Sustainability is becoming a major consideration in the digital ink market. Manufacturers are under pressure to develop formulations that are less harmful to the environment and safer for human health. As a result, eco-solvent and water-based digital inks are gaining traction, especially in applications like indoor signage, textiles, and children’s products. Additionally, digital printing in general produces less waste and uses fewer resources compared to traditional methods, making it a greener alternative in many use cases.

Regionally, North America and Europe hold significant market shares due to their established printing industries and early adoption of advanced technologies. However, the Asia-Pacific region is witnessing the fastest growth, fueled by the expansion of manufacturing, packaging, and textile industries in countries like China, India, and Japan. As digital infrastructure and consumer demand grow in these regions, so does the need for high-performance digital inks.

Technological advancements are also driving market innovation. The development of nano-pigments, conductive inks for electronics, and bio-based inks are opening new application areas for digital ink. In sectors like printed electronics and 3D printing, digital inks are being used to create functional parts, circuits, and prototypes, which was previously not possible using conventional inks. These applications require inks that perform under specific environmental and mechanical conditions, leading to a surge in RD investment in this space.