Introduction to Uniaxial Geogrid

Uniaxial geogrid is an innovative engineering material primarily used to reinforce earth structures. It plays a crucial role in various civil engineering applications, helping to improve the stability and load distribution of soils. Made of polymer, Uniaxial geogrid exporters in Ahmedabad are designed with a specific arrangement that enhances their tensile strength in one direction, making them particularly effective for soil reinforcement. As urbanization and infrastructure development continue to rise, so does the demand for quality geosynthetics, particularly from uniaxial geogrid exporters in Ahmedabad.

Applications of Uniaxial Geogrid

Uniaxial geogrids find extensive applications in civil engineering projects. One of their primary uses is in road construction, where they help in reinforcing sub-base and base layers. Uniaxial geogrid manufacturers in Ahmedabad This reinforcement dramatically improves the lifespan of pavement and reduces maintenance costs. Additionally, uniaxial geogrids help in stabilizing embankments and retaining walls, preventing soil erosion and providing additional support to vertical structures.

Moreover, these geogrids are applied in various other domains, including landfill construction, slope stabilization, and drainage systems. The versatility of uniaxial geogrids makes them vital components in effective soil management, and as such, they have become a focus for uniaxial geogrid manufacturers in Ahmedabad, who strive to produce high-quality, reliable products.

Advantages of Using Uniaxial Geogrid

The advantages of uniaxial geogrids are manifold. Uniaxial geogrid exporters in India First and foremost, their unique design allows for superior tensile strength, meaning they can withstand significant loads without deformation. This characteristic ensures long-lasting stability for the structures they support. Furthermore, uniaxial geogrids facilitate efficient load distribution across a broader area, reducing the stresses acting on the underlying soil. This is particularly beneficial in areas prone to settlement or movement.

Another critical advantage is the ease of installation. Uniaxial geogrids can be quickly laid out, allowing for reduced construction times and lower labor costs. Their lightweight nature also makes them easy to transport and handle on-site. This combination of efficiency, strength, and cost-effectiveness has led to increased interest from uniaxial geogrid exporters in India, who recognize their market potential.

The Role of Uniaxial Geogrid Exporters in Ahmedabad

Ahmedabad has emerged as a notable hub for uniaxial geogrid exporters in India. This city is characterized by a rich industrial base and a growing infrastructure sector, which fuels demand for innovative materials like uniaxial geogrids. Local exporters ensure that engineers and contractors have access to top-quality geosynthetics that meet national and international standards.

By leveraging advanced manufacturing technologies, these exporters are continually improving the quality of uniaxial geogrids while reducing costs. They often engage in partnerships with numerous civil engineering firms, sharing insights on best practices and seamless application methods. This dynamic relationship enhances the responsible use of uniaxial geogrids in various projects across the country.

Key Characteristics of Uniaxial Geogrids

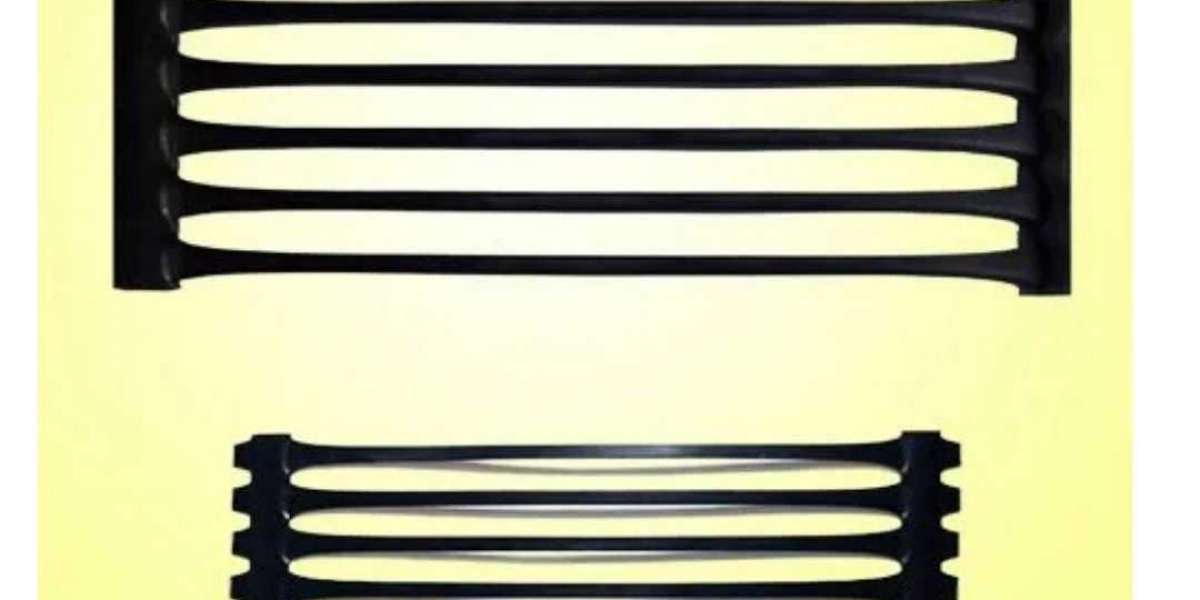

Uniaxial geogrids are crafted with specific material properties that define their performance. High-density polyethylene (HDPE) and polypropylene (PP) are commonly used materials, chosen for their strength-to-weight ratio and resistance to degrading agents.

The manufacturing process includes heating and stretching the raw material, aligning the polymer chains in one direction to increase tensile strength. Notably, uniaxial geogrids feature apertures designed to facilitate soil interlocking, promoting effective load transfer and acting against soil movement.

Sustainability is another essential aspect of modern uniaxial geogrid production. Manufacturers are increasingly adopting eco-friendly practices to minimize environmental impact, appealing to an environmentally conscious market. This trend aligns well with global construction demands and makes these products attractive to both local and international market segments.

Future Trends in Uniaxial Geogrid Production

The future of uniaxial geogrid technology is promising, with ongoing innovations expected to push the boundaries of their applications. New technological advancements may allow for the development of more versatile geogrids capable of withstanding diverse environmental conditions, such as extreme temperatures and corrosive soils.

Moreover, the integration of digital technologies, such as Geographic Information Systems (GIS) and Building Information Modeling (BIM), can enhance project planning and execution involving geogrid applications. Utilizing data-driven approaches will help optimize the effectiveness of uniaxial geogrids, further boosting their relevance in the modern engineering landscape.

As manufacturers in Ahmedabad and beyond face challenges related to sustainability and environmental compliance, research and development will become increasingly vital. Companies focused on eco-friendly materials may capture a larger share of the market, ensuring longevity in a highly competitive industry.

Conclusion

In summary, uniaxial geogrid is a fundamental material in contemporary civil engineering, offering vital support for various applications. Its advantages in terms of strength, ease of installation, and cost-effectiveness make it a preferred choice among engineers and contractors. With a robust network of uniaxial geogrid manufacturers and exporters in Ahmedabad and throughout India, the future looks bright for this essential civil engineering material.

FAQs about Uniaxial Geogrid

1. What is the primary function of uniaxial geogrids in civil engineering?

Uniaxial geogrids primarily function to reinforce soil structures, improving stability and load distribution in applications like road construction, retaining walls, and slopes.

2. How are uniaxial geogrids manufactured?

Uniaxial geogrids are typically made from high-density polyethylene and polypropylene. The manufacturing process involves heating and stretching the material to align its polymer chains in one direction, enhancing tensile strength and resistance.

3. What advantages do uniaxial geogrids offer compared to other reinforcement methods?

Uniaxial geogrids offer several advantages, including high tensile strength, efficient load distribution, ease of installation, and cost-effectiveness, making them a popular choice for civil engineers and contractors.